Principle of Screen Printing

Screen printing process is the ink through some of the mesh of the screen plate after the leakage of printing on the substrate, the rest of the mesh of the screen plate is blocked, the ink can not come through. Printing ink poured on the screen, in the absence of external force, the ink will not leak through the mesh to the substrate, and when the squeegee to a certain pressure and tilt angle of the ink when scraping, it will be transferred to the substrate through the screen below so as to realize the image of the reproduction.

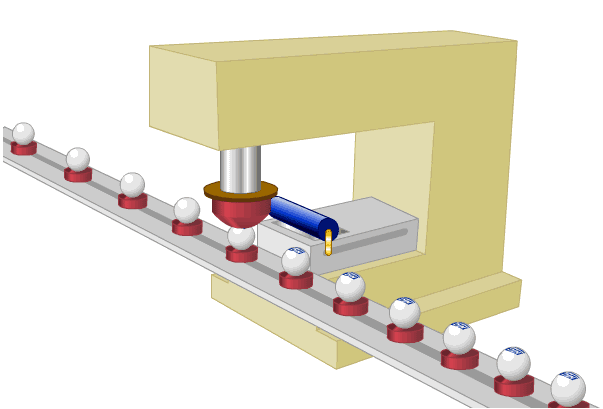

Principle of pad printing

The basic principle of pad printing is that in the pad printing machine, the ink is first put into the engraved text or pattern steel plate, and then the text or pattern is copied to the rubber through the ink, and then the rubber is used to transfer the text or pattern to the surface of the plastic product, and it is best to make the ink curing through heat treatment or ultraviolet light irradiation and other methods.

01Screen Printing Features

Wide range of substrates

Since the printing plate is made of silk screen, it is soft and flexible, so the substrate can be printed whether it is flat or curved, hard or soft, large or small. In addition, screen printing can be used on fragile and deformable substrates due to low pressure.

Thick ink layer and high covering power

Screen printing has a thick ink layer that is unrivaled by other printing methods. For example, if white is used to cover the base color below, ordinary printing methods require 3 to 4 times of printing on the same part, while screen printing can be completed in just one pass. Screen printing ink layer thickness is generally 20 microns, special thick film printing up to 100 microns, the thinnest also has 6 microns. Therefore, the ink layer of silk screen printing is thick and adjustable in a wide range.

Strong three-dimensional sense

Because of the thick ink layer, so in the imitation of prints and reproduction of the effect of oil painting is very realistic, its color greatly exceeds the offset printing. However, in the printing of fine patterns, the reproduction effect is limited to a certain extent.

Good light resistance

After mixing light-resistant pigment and fluorescent pigment in the ink, the printed pattern can keep luster permanently without being affected by temperature and sunlight, and can even glow at night. Therefore, screen printing products are suitable for outdoor advertising, signs and so on.

Applicable inks

Water-based, oil-based, solvent-based and so on, and even available slurry, paste, powder. Therefore, screen printing inks are collectively called printing materials.

Large printing area

In terms of printing area, general offset printing, letterpress printing and other methods due to the limitations of mechanical equipment and far less than screen printing. Screen printing maximum width of 3M * 4M or even larger.

Printing plate has greater scalability

The characteristics of the screen material determines the printing plate will have a large expansion and contraction. When used for large-volume printing, the easy stretching of the printing plate will affect the reproduction effect.

02 Pad printing characteristics

Pad printing is mainly done through the adhesive tip to complete the transfer process, so the printing process is limited by the performance and shape of the adhesive tip. Adhesive head has the characteristics of elasticity, curved shape, and cannot be infinitely large.

In principle, it can be said that as long as the tip deformation can reach the place can be printed. Therefore, pad printing can be applied to a wide range of areas, but the printing range of pad printing has a rough outline judged from the characteristics of the adhesive head, and it is not possible to print a large area of the pattern.

Wide range of applications

Pad printing meets the requirements of beautiful appearance and good quality, thus making the printed products more gorgeous. Its field of application is developing rapidly, so that we have to face more and more pad printing products every day. Such as decorations, clocks and watches, glass bottles, labels, etc.; toys, stationery, light box advertising and so on.

Direct Printing

In the special pad printing machine using pad printing adhesive head on the plane intaglio ink graphics dipped in the print, and then by the pad printing adhesive head will be transferred to the ink graphics on the substrate.

Screen printing has many advantages

Such as a wide range of adaptability to the substrate, low cost, you can use the vast majority of screen printing ink. However, pad printing is mostly used for small flat surface, concave and convex surface of the graphic printing, printing flexibility and easy to register color.

The perfect match for screen printing

Screen printing can print flat surfaces such as flat, spherical, curved, angular or concave, and can print on objects with multi-color wet pressing without drying between colors.

03Difference between pad printing and screen printing

Principle

Pad printing: The pattern engraved on the steel plate is transferred to the workpiece by the action of the adhesive tip, similar to the stamping in daily work.

Silk-screen printing: Through the pressure of the squeegee, the ink penetrates into the product from the mesh of the screen plate, forming a pattern.

Printing area

Pad printing: the printing area of pad printing has a certain limit

Pad printing: the printing area is basically unlimited, the cost of consumables (screen) is lower, and can be reused.

Product shape

Pad printing: there is no limit to the shape, flat, curved, wavy, as long as the tip deformation can reach the place can be printed.

Screen Printing: The printing surface of the product should be flat, purely flat or regular curved surfaces.

Color registration

Pad printing: Pad printing machine can do up to 12 color sets in one machine, one time to print the product, and the cost is low, suitable for general factory investment.

Screen printing: screen printing machine can also do multi-color overprinting, but multi-color overprinting screen printing machine price is very expensive, is not suitable for general factory investment, manual walking table one-time multi-color overprinting occupies a large area, more labor.

Ink layer

Pad printing: pad printing ink layer is thin, can be printed on any surface color overprinting, showing very good color performance and printing adaptability, commonly known as universal printing, in addition to water and air can not be printed, any object can be used pad printing printing

Screen printing: The ink layer of screen printing is thick, the printed pattern has a strong sense of three-dimensionality, and can be touched by hand, which is suitable for the surface printing of high-grade products, the color expression is very good, multi-color overprinting is more troublesome, and the surface of the product is required to be a regular plane or curved surface, which has a certain limitation of the printing range.

In short, screen printing can print flat or curved surfaces with large surface areas and flat surfaces; pad printing can print small products with multi-color overprints, and has no requirements for product shapes.

Contact us

If you need product information or price of paper tapepaper bag and paper box, please click on our email address info@bochenpaper.com to send us an email to get prompt reply Or leave your contact information by clicking on the chat tool in the lower right corner.